When exploring the materials used in the manufacture of cheap belt buckles, it’s essential to delve into the variety and reasons behind the selection of specific materials. The choice is driven by cost, ease of production, durability to some extent, and aesthetics. Here, I’ll unpack the common materials found in low-cost belt buckles, touching upon their characteristics and why they’re preferred in the budget segment of the market.

Zinc Alloy

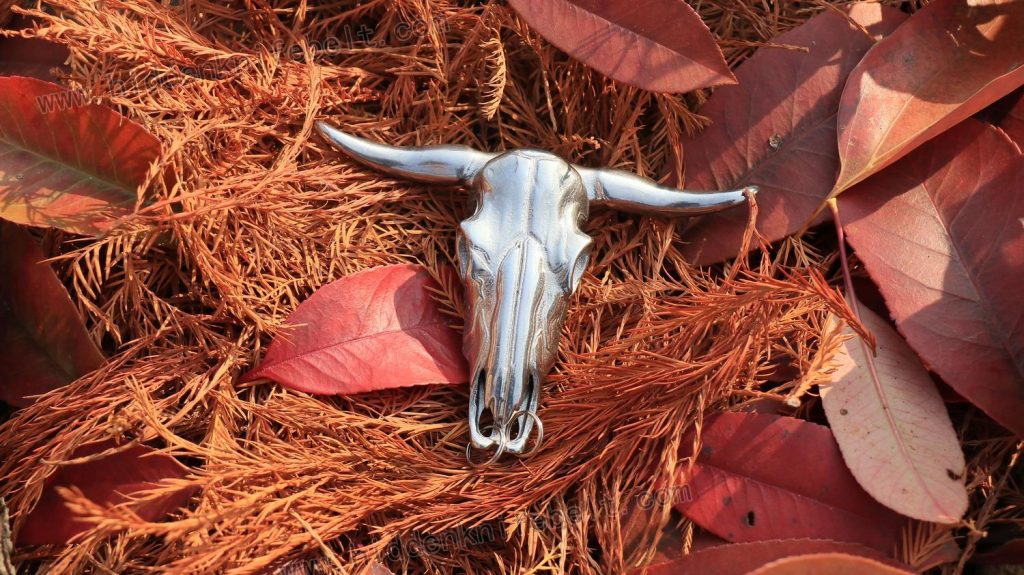

One of the most prevalent materials in the production of inexpensive belt buckles is zinc alloy. Zinc alloy is a material beloved by manufacturers for its excellent balance between cost-effectiveness, malleability, and durability. This alloy, often combined with small amounts of aluminum, copper, and magnesium, can be easily cast into intricate shapes and designs. This versatility allows for a wide variety of buckle styles, even at lower price points. Moreover, zinc alloy belt buckles can be finished with various platings—such as silver, gold, or antique finishes—to enhance their appeal without significantly increasing the cost.

Plastic

Plastic is another material frequently used in the manufacture of budget-friendly belt buckles. With advancements in polymer technology, plastics can be engineered to mimic the look of more expensive materials like metal or wood, offering consumers aesthetic choices at a fraction of the price. Plastics are lightweight, resistant to corrosion, and can be produced in a vast array of colors and textures. Their moldability allows for the creation of designs that might be more challenging or expensive to achieve with metal. However, plastic buckles may not offer the same level of durability as their metal counterparts and can be prone to breakage under strain.

Stainless Steel (Low-Grade)

Low-grade stainless steel is another material commonly found in cheaper belt buckles. While stainless steel is renowned for its strength and resistance to corrosion, the lower grades of this metal are more affordable and thus a popular choice for budget-conscious production. These lower grades might not have the same corrosion resistance or finish quality as higher grades but still provide a more durable option than plastic or certain alloys. Stainless steel buckles can be stamped or cast into shape, offering a decent balance between cost and durability.

Brass or Copper (Thin Plating)

In some cases, inexpensive belt buckles might use a base of a cheaper metal, such as zinc alloy or even plastic, coated with a thin layer of brass or copper. This approach allows manufacturers to produce buckles that have the appearance of being made from these more traditional materials while keeping costs down. The plating can give the buckle a classic or vintage look, appealing to consumers looking for style on a budget. However, the thin layer of plating may wear off over time, especially with frequent use or exposure to the elements.

Final Thoughts

In the realm of cheap belt buckles, the use of materials such as zinc alloy, plastic, low-grade stainless steel, and thinly plated brass or copper exemplifies the industry’s effort to balance cost, functionality, and aesthetic appeal. Each material brings its own set of advantages and limitations, shaping the final product’s market positioning. While these materials make belt buckles accessible to a broader audience by keeping prices low, they also reflect a compromise—primarily in durability and, to some extent, in aesthetic longevity. Nonetheless, for consumers seeking variety and style at an affordable price, these materials offer a range of options that cater to diverse tastes and needs.